Like highways, asphalt parking lots require regular maintenance to realize their lifespan. Routine maintenance can increase the lifespan of asphalt pavements while enhancing the aesthetic value of the property. Here are some helpful facts about hot mix asphalt (HMA) and best practices to consider to ensure the path that leads customers to your front door leaves a positive first impression.

Your new pavement will become softer or harder as temperatures rise and fall.

Unlike concrete, HMA is designed to be flexible. During the first year or so, while the pavement oxidizes, be careful not to turn steering wheels while vehicles are stationary, because it may cause some “scuffing” of the pavement surface. Initially, scuffed areas may not look aesthetically pleasing, but they will visually improve over time with no structural damage.

Excessive weight from large vehicles may create depressions in the new pavement.

If you park trailers, motorcycles, or bikes on the new asphalt surface, we recommend placing a large flat item under the tongue, wheels, and kickstands to spread the load, particularly during warm weather.

The surface of the new pavement may look slightly different in some areas because of the composition of HMA.

HMA is made up of various sizes of stone, sand, liquid asphalt, and other components. Whether spread with a paver or by hand, it is common to have different surface textures; however, this should not affect the longevity of your pavement.

When cracks develop, fill with a commercially available rubberized crack filler.

This will reduce moisture infiltration into the underlying materials and help prolong the life of the pavement. When appropriate, it is recommended to route cracks to make adequate space for the crack filler.

We made every effort to avoid leaving low spots on your pavement, but some moisture could develop depending on the natural slope and drainage of your property.

Buried stumps, rocks, roots, and other materials underneath the base course can cause surface irregularities or even depressions over the years from frost action, settlement of the subgrade, organic decay, and thermal expansion/contraction.

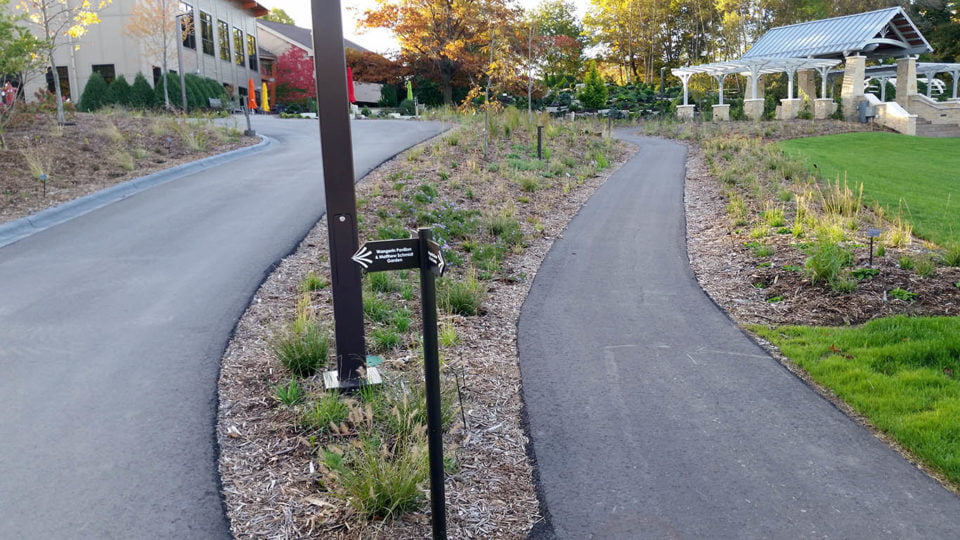

To protect and help support the edges of the new pavement, we recommend that you install stone, gravel, or topsoil around its perimeter.

This acts much the same as a shoulder on a highway. It will help to control erosion on sloping pavements, support the pavement edges and enhance the appearance of the pavement.

Avoid leaks or spills of gasoline, fuel oil, lubricants, and other petroleum-based products on the pavement.

These products will eventually dissolve the asphalt cement component of the HMA and damage the pavement. If you do notice these products on your pavement, scrub the area thoroughly with soap or detergent and rinse well with water.